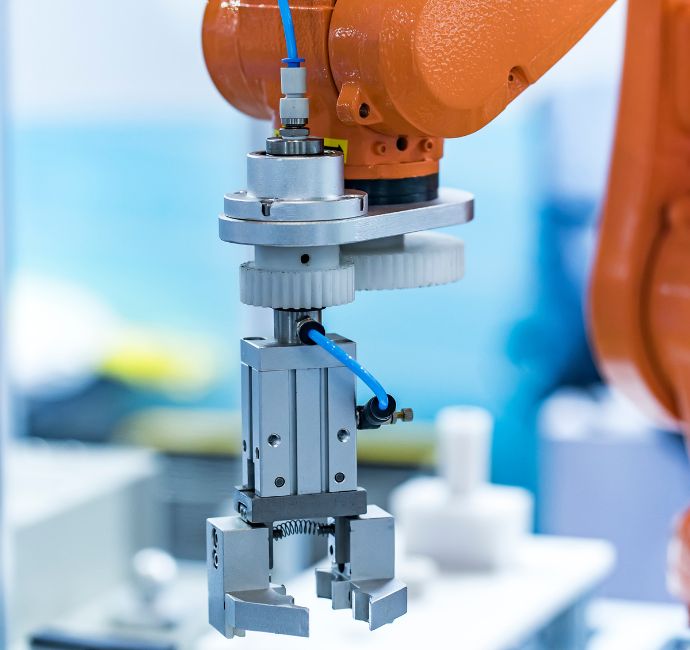

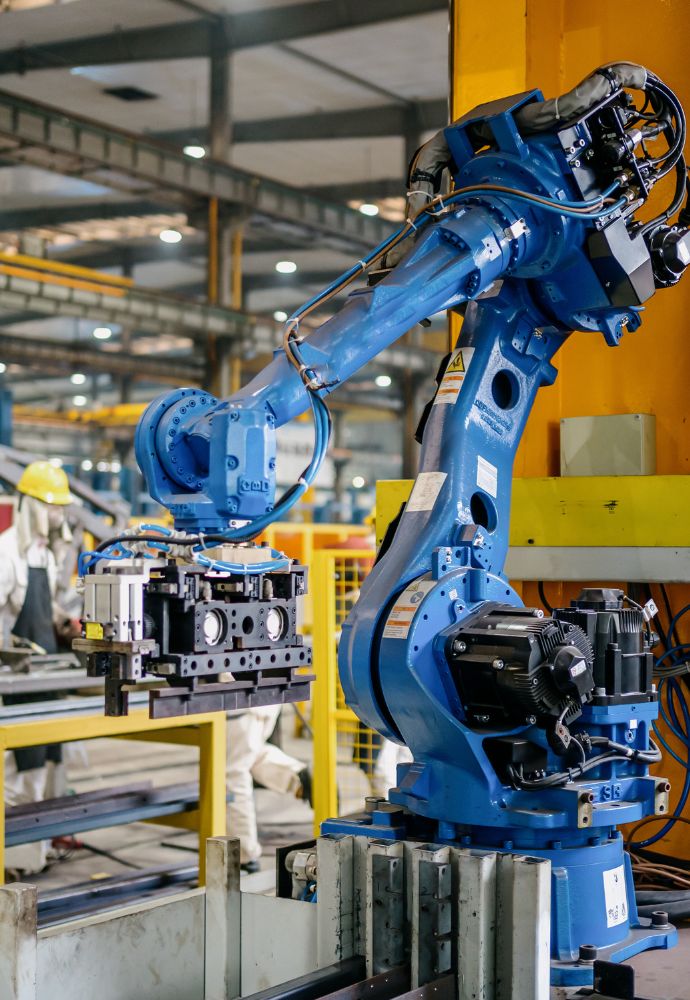

Robotic material handling involves using robots to move objects efficiently. By equipping the robot with a suitable end-of-arm tool, it can transport products quickly and accurately between locations. These robots help automate repetitive, boring, and potentially hazardous tasks in manufacturing processes. Adding robotic material handling is an effective way to improve automation while enhancing productivity. They ensure faster operations, improved product quality, and better customer satisfaction.

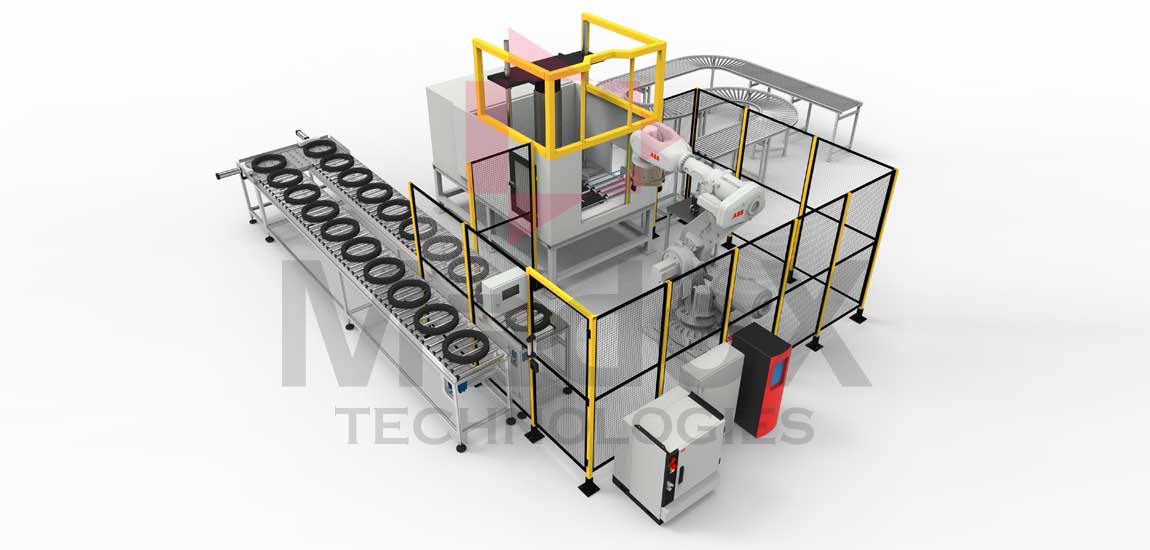

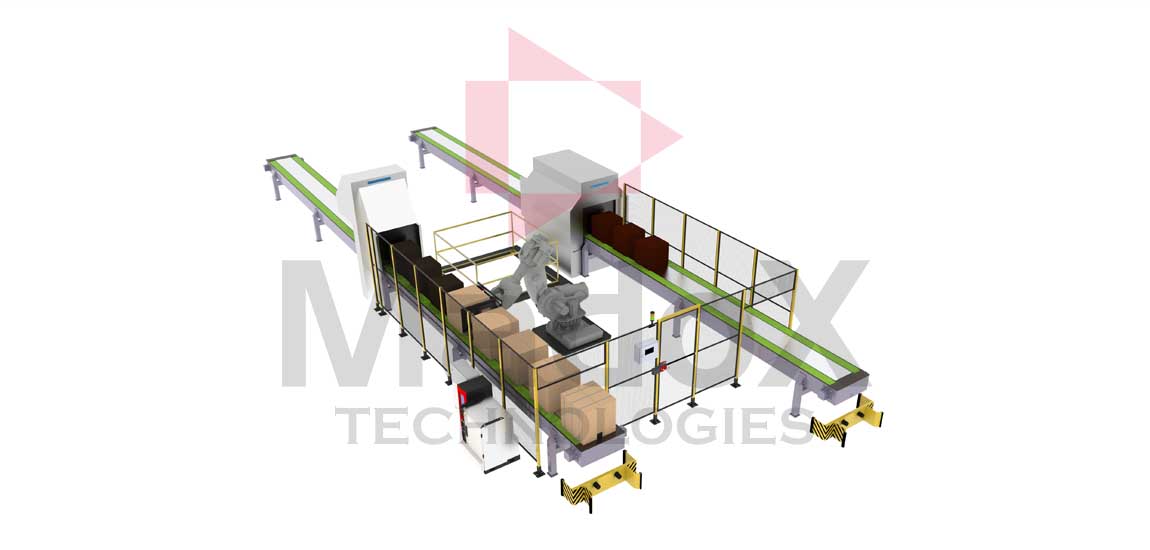

Our robotic palletizers are space-saving compared to traditional conveyor systems. Unlike fixed conveyor setups, robotic palletizers offer flexible and scalable solutions. Their modular design allows businesses to expand palletizing capabilities to match growing demand or support new product lines. Unlike fixed conveyor setups, these material handling robots offer flexible and scalable automation. Integrating these units into your current production space is simple, as they are self-contained and adaptable to existing workflows.

Here are some common robotic material handling solutions we offer:

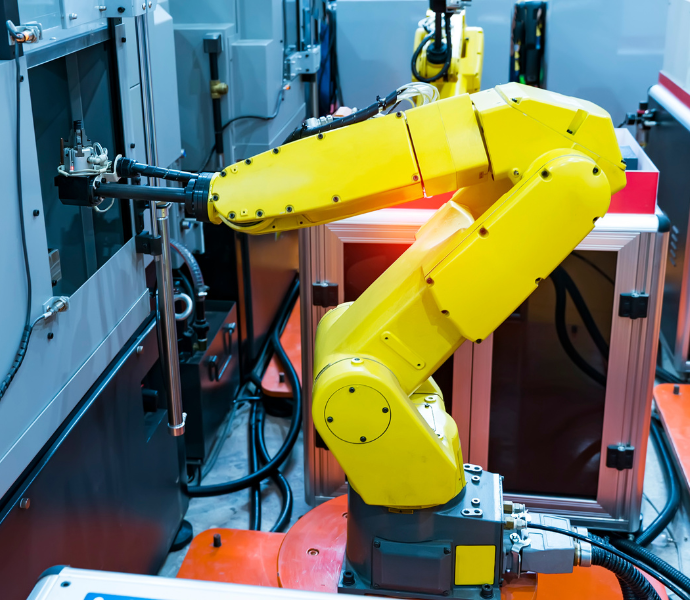

- Collaborative Robot (COBOT) solutions for machine tending

- Rail or Gantry systems for loading multiple machines

- Injection molding solutions for tasks such as component removal, screw cutting, decorating, labeling, and adding inserts

- Vision-guided bin picking systems for handling random objects

- Sheet metal press tending and stamping solutions

- Forge tending solutions for loading, unloading, and punching processes

- Robotic pick-and-place systems

- Robotic palletizing solutions

- Robotic part transfer systems

- Robotic assembly solutions

- Robotic holding and teamwork solutions

- Robotic conveying systems

- Robotic packaging solutions

- Robotic bin picking systems

- Robotic sorting solutions

- Robotic labeling and marking solutions

- Robotic material removal solutions

Our robotic solutions for material handling help reduce downtime and remove the need for risky, tiring, or repetitive tasks in industrial settings. We focus on delivering customized solutions that improve cycle time and offer enhanced flexibility. We know that investing in industrial robots and robotic material handling systems is a big decision, so ensuring proper integration from the start is crucial. With our expertise, we provide cost-effective solutions with improved flexibility.

Our robotic palletizers are compact and take up less space compared to traditional conveyor systems. They offer greater flexibility, allowing easy scaling to match growing demands or new product lines. Thanks to their modular design, robotic palletizers are easy to integrate into existing production setups, making them a convenient choice for enhancing workflow efficiency.

In addition to standard tending tasks, MadoX provides a wide range of advanced solutions tailored to various industries:

- Collaborative Robot (COBOT) Handling: Efficient handling solutions using COBOTs for seamless automation.

- SCARA Robot Handling: Ideal for tasks requiring quick movements and short reach.

- Foundry & Forge Solutions: Expert handling of casting extraction, die insert placement, and sand core management.

- Food Industry Solutions: Reliable robots designed for safe and efficient picking and packing processes.

- Pharmaceutical Industry Solutions: Fast and secure sorting, picking, and packing solutions for pharmaceutical products.

- Electronics Industry Solutions: Quick sorting, precise picking, and expert soldering automation.

- Mixed Palletizing Solutions: Vision and 3D area sensor solutions for multi-pick, sorting, layering, and product alignment.

- Material Removal Solutions: Automated deburring, drilling, polishing, and grinding solutions for precision work.

- Item Detection Solutions: Vision and 3D area sensor systems designed for part size recognition and type identification.

- Coordinated Motion Solutions: Advanced robot synchronization for effective teamwork and seamless operations.

Robotic material handling involves using robots to efficiently move objects from one place to another. By equipping robots with suitable end-of-arm tools, they can carry out tasks accurately and quickly. These robots are ideal for automating repetitive, monotonous, and hazardous jobs in a production line, making automation easier to implement. Robotic material handling improves productivity and ensures timely delivery of quality products, enhancing customer satisfaction.

Some common robotic material handling solutions we offer include:

- Collaborative Robot (COBOT) for machine tending

- Multi-machine loading with rail or gantry systems

- Injection molding support such as component removal, screw cutting, decorating, labeling, and adding inserts

- Vision-based bin picking for loading random objects

- Sheet metal press tending and stamping

- Forge tending for loading, unloading, and punching

- Robotic pick and place systems

- Robotic palletizing

- Robotic part transfer

- Robotic assembly

- Robotic holding and teamwork

- Robotic conveying systems

- Robotic packaging solutions

- Robotic bin picking systems

- Robotic sorting solutions

- Robotic labeling systems

- Robotic marking systems

- Robotic material removal solutions

Our robotic solutions for material handling are designed to reduce downtime and minimize the need for strenuous, repetitive, or hazardous labor in industrial settings. We are committed to providing customized tending solutions that offer improved cycle times and enhanced flexibility. We recognize that investing in industrial robots is a significant decision, and ensuring proper integration from the start is crucial. With our expertise, we deliver cost-effective solutions that maximize flexibility and performance.

In addition to standard tending tasks, MadoX offers a wide range of comprehensive solutions, including:

- Collaborative Robot (COBOT) Handling: Ensuring safe and efficient material handling using collaborative robots.

- SCARA Robot Handling: Ideal for applications requiring short reach and rapid movement.

- Foundry & Forge Solutions: Specializing in casting extraction, die insert placement, and handling of sand cores.

- Food Industry Solutions: Providing secure and efficient robot solutions for picking and packing.

- Pharmaceutical Industry Solutions: Ensuring safe, quick sorting, picking, and packing solutions for pharma operations.

- Electronics Industry Solutions: Offering fast sorting, picking, and soldering robot solutions.

- Mixed Palletizing Solutions: Utilizing vision and 3D area sensors for multi-pick, sorting, layering, and orientation.

- Material Removal Solutions: Delivering precise solutions for deburring, drilling, polishing, and grinding.

- Item Detection Solutions: Employing vision and 3D area sensors for accurate part size and type recognition.

- Holding & Teamwork Solutions: Ensuring synchronized motion functionality with multiple coordinated robots.

Robotic system integration involves designing, building, operating, and applying industrial robots to streamline various tasks. At Madox, we specialize in developing innovative and cost-effective robotic solutions tailored for both complex processes and routine operations.

We offer customized robotic cell solutions featuring leading robot brands such as ABB, Fanuc, Yaskawa, Kuka, and more, catering to industries across Malaysia. With over a decade of experience in robotics automation, we have successfully designed and implemented numerous robotic systems for diverse applications.

Our process starts by carefully understanding client requirements to ensure the best possible solution is integrated into their production systems. Our skilled in-house engineering team evaluates your specific application needs, incorporating the latest technologies to deliver efficient and effective results.

From initial consultation to final deployment, our process ensures seamless integration of robotic material handling systems, maximizing your productivity and ROI. Our commitment to quality, reliability, and innovation makes us a trusted turnkey provider for material handling robots. We have helped numerous manufacturers reduce operational costs and enhance long-term efficiency.

Our team holds extensive expertise in handling various robotic applications, integrating different robot types, and designing peripheral equipment to suit your production demands.