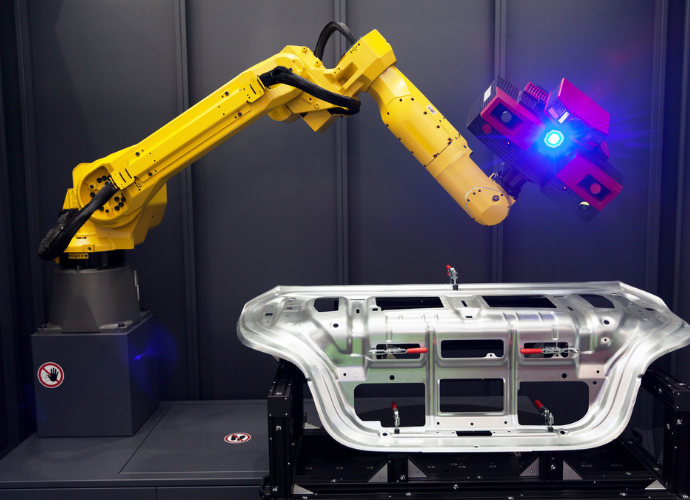

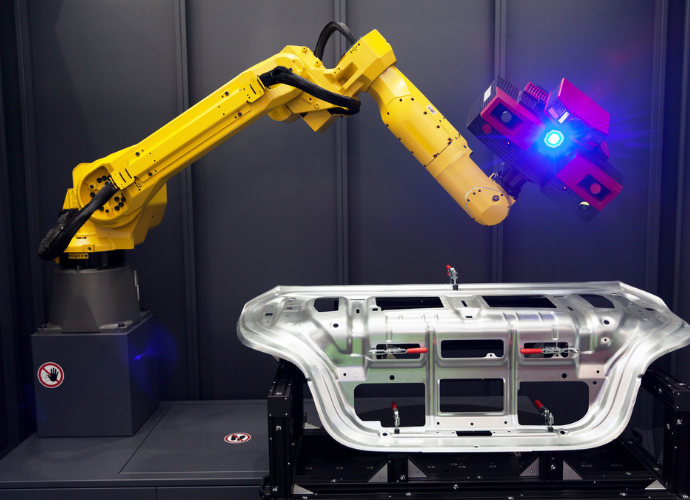

Inspection robots are mobile service robots equipped with advanced vision sensors, designed to inspect critical and high-value infrastructure. These robots can be semi-autonomous, following pre-programmed paths, or fully autonomous, navigating independently. We offer robotic inspection solutions using vision-based systems or in collaboration with Coordinate Measuring Machines (CMM). Collaborative Robots, also known as COBOTS, are commonly employed in inspection applications.

In manufacturing environments, achieving precise and dependable inspections can often become a bottleneck in the production process. Industrial robotic inspection systems help resolve this by improving efficiency and ensuring inspections do not slow down production. Our solution allows robots to manage workpieces for stationary quality inspection sensors or present parts directly to human inspectors for visual assessment. Additionally, robots can operate inspection tools such as various sensors and metrology measuring heads, ensuring accurate and streamlined inspection processes.

Industrial robots are highly effective in improving accuracy and productivity for industrial inspection tasks. Robots and cobots are increasingly used in quality control processes, efficiently moving workpieces in front of sensors or through inspection stations.

At MadoX, we provide robust robotic inspection solutions tailored for a wide range of industry applications, including:

- Collaborative Robot (COBOT) Inspection: Ensures precise and safe inspection processes.

- Robotic Vision Inspection: Uses advanced vision cameras for accurate visual checks.

- Sensor-Based Robotic Inspection: Utilizes specialized sensors for different applications.

- Welding Inspection: Offers solutions for assessing the quality of arc welding.

- Functional Testing: Ideal for repeated cycle tests to ensure product reliability.

- Chemical Sampling: Designed for safe inspection of hazardous materials.

- Medical Equipment Inspection: Ensures the functionality and accuracy of medical devices.

- Aerospace Component Inspection: Provides precise inspection for high-precision aerospace parts.

MadoX ensures every solution is customized to meet the specific needs of our clients, enhancing inspection and quality control in manufacturing and boosting overall operational efficiency.

Robotic system integration involves designing, building, operating, and applying industrial robots. At Madox, we specialize in providing smart, cost-effective robotic solutions tailored for both complex and routine tasks.

Our services go beyond supplying robots—we specialize in full inspection robots manufacturing and robotic system integration. We deliver robotic cell solutions using trusted brands such as ABB, Fanuc, Yaskawa, Kuka, and other renowned robot manufacturers available in Malaysia. With over a decade of experience in robotic automation, we have successfully designed and installed numerous robotic systems across various industries.

At Madox Technologies, we prioritize understanding our clients’ needs to offer solutions that enhance their processes and improve efficiency. Our skilled in-house engineering team carefully evaluates each application to implement the most suitable technology for seamless integration. We are committed to delivering reliable and high-quality robotic solutions with innovative designs.

As a trusted turnkey solutions provider, Madox has helped numerous manufacturers reduce operational costs and achieve sustainable growth. Our team holds extensive expertise in handling various robotic applications, robot types, and designing and manufacturing peripheral equipment.