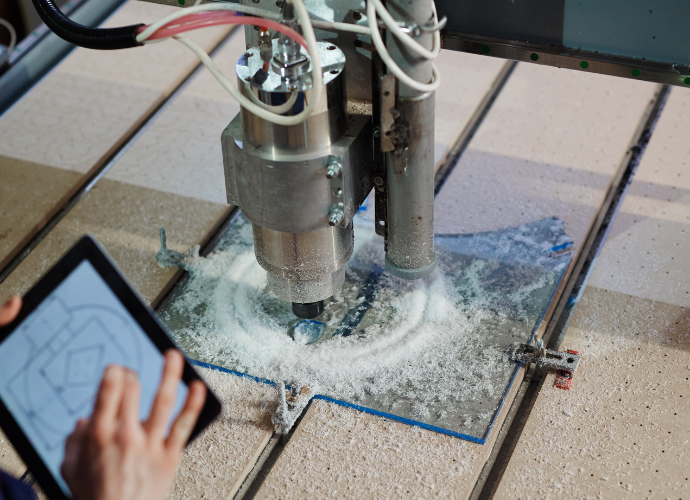

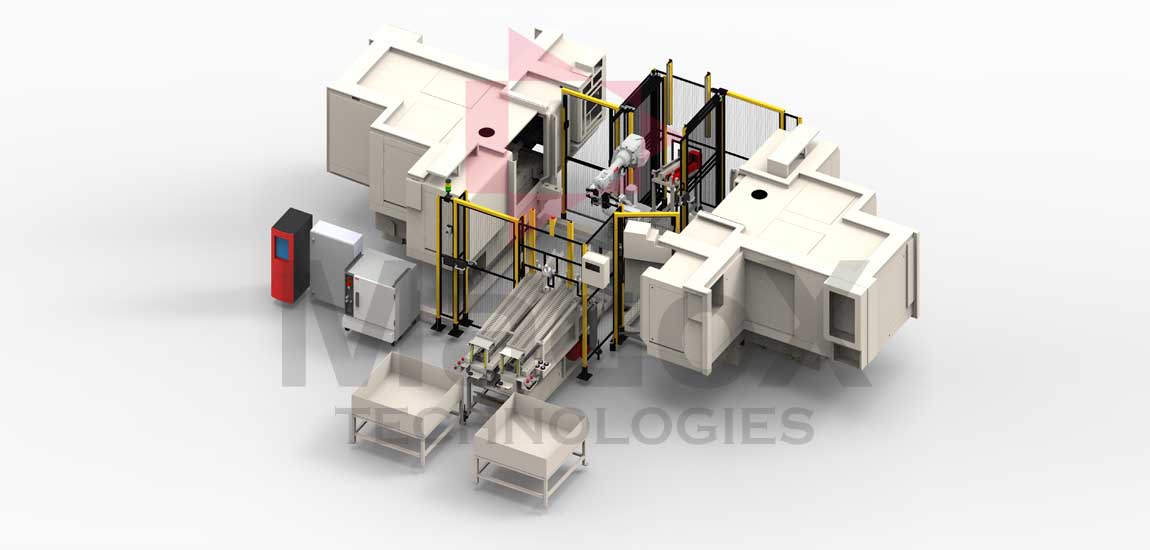

Robotic machine tending refers to the automated process of loading and unloading parts into industrial machines using robotic systems. Our robotic machine tending solutions are designed to support various industrial processes, including CNC machining, press work, specialized machining, die casting, molding, and grinding.

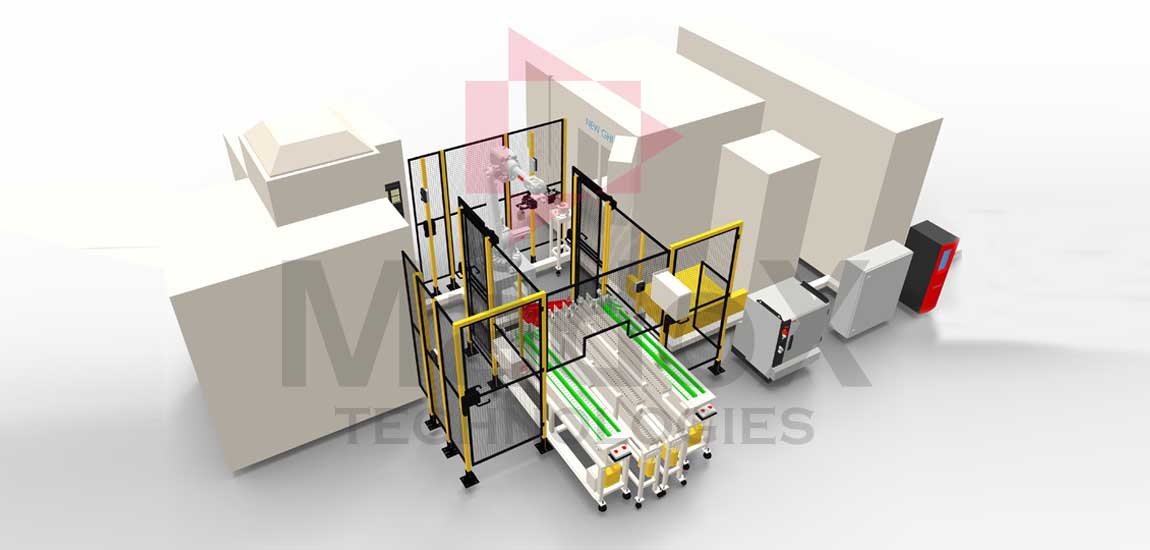

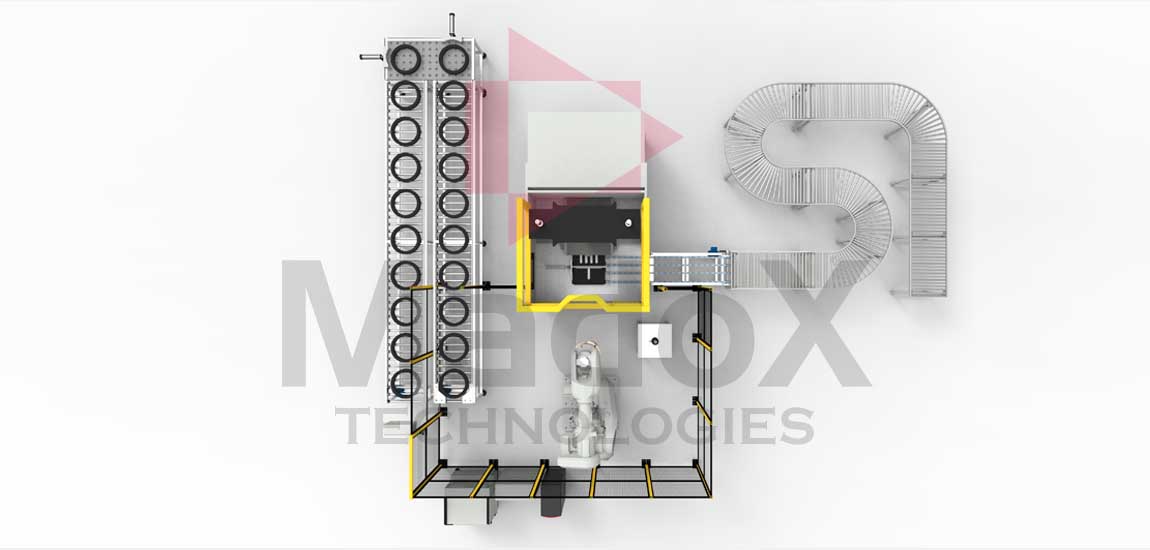

Since each application can vary in terms of layout, workflow, workpieces, and specific requirements, we customize our machine tending solutions based on detailed site studies and simulations to ensure optimal results.

Our solutions also extend to automating additional manual tasks such as:

- Inspecting input parts

- Inspecting output parts

- Marking

- Blow-off cleaning

- Washing

- Deburring

- Sorting

- Packing

The use of robotic machine tending in manufacturing industries is growing rapidly due to its numerous benefits, such as improved productivity, enhanced quality, reduced need for manual labor, increased safety, and lower operational costs.

We are committed to providing customized tending solutions that ensure efficient cycle times and excellent flexibility. Understanding that industrial robots are a significant investment, we focus on ensuring seamless integration right from the start.

With extensive experience in the field, we deliver flexible solutions at competitive prices. Our expertise lies in offering machine tending robot automation solutions for Foundry and Forging applications. Automation in these industries requires specialized knowledge, and since our company’s inception, we have been actively working in this sector. Over the years, we have successfully installed multiple machine tending cells for hot forge material handling applications.

In addition to regular tending tasks, MadoX provides a complete range of automation solutions designed to enhance efficiency and precision:

- Collaborative Robot (COBOT) Tending – Streamline your machine tool tending processes using COBOT technology.

- Multi-Machine Loading – Efficient solutions using rail or gantry systems for seamless machine loading.

- Injection Molding Solutions – Automate tasks such as component removal, screw cutting, decoration, labeling, and insert placement.

- Random Object Loading – Advanced vision-based bin picking solutions for handling various objects.

- Press Tending – Automated sheet metal press tending and stamping solutions.

- Forge Tending – Efficient handling for loading, unloading, and punching operations.

- Diecasting Solutions – Automate component removal, trimming, and coolant spraying for improved productivity.

- Welding Assistance – Precision product holding solutions for welding operations.

Robotics system integration involves designing, building, operating, and implementing industrial robots. At MadoX, we specialize in developing smart and budget-friendly machine tending robot automation solutions for both complex processes and routine tasks. We offer robotic machine tending cell solutions using ABB, Fanuc, Yaskawa, Kuka, and other leading robot brands available in India.

With over 10 years of experience in the robotics automation industry, we have successfully designed and deployed numerous robotic systems across the country for various applications. Our process starts with understanding our customers’ specific needs and identifying ways to improve their production process through efficient robotic integration.

Our skilled in-house engineering team carefully evaluates your application requirements and implements the latest technology to deliver effective solutions. We focus on innovative designs to ensure our machine tending robot systems are reliable and high in quality.

As a trusted turnkey solutions provider, Madox has consistently helped major manufacturers lower operational costs and improve long-term sustainability. Our team has extensive experience in managing various robotic applications, robot types, and designing and producing peripheral equipment to complement these systems.