MadoX is a trusted provider of turnkey automation solutions. We specialize in both robotic process automation and industrial automation services, offering tailored Engineering Services to assist customers and system integrators in setting up smart automation systems using Industrial Robots and Motion Control. With experience collaborating with top automation brands like Fanuc, ABB, Yaskawa, and KUKA, we deliver comprehensive programming solutions, including simulation and analysis for complex industrial applications.

Our services also include project consultation to help integrate automation into your production line, enhancing safety, quality, cost efficiency, and overall performance.

Robot Simulation & Offline Programming

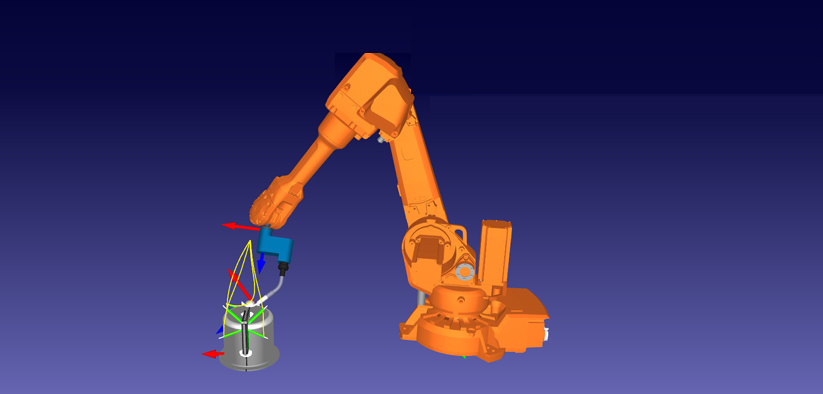

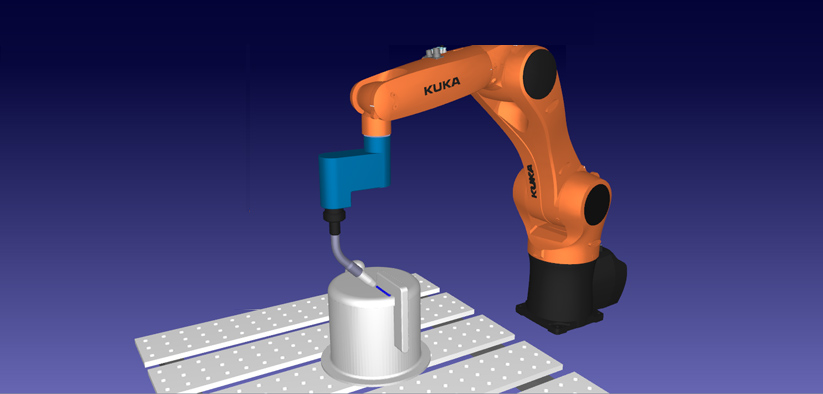

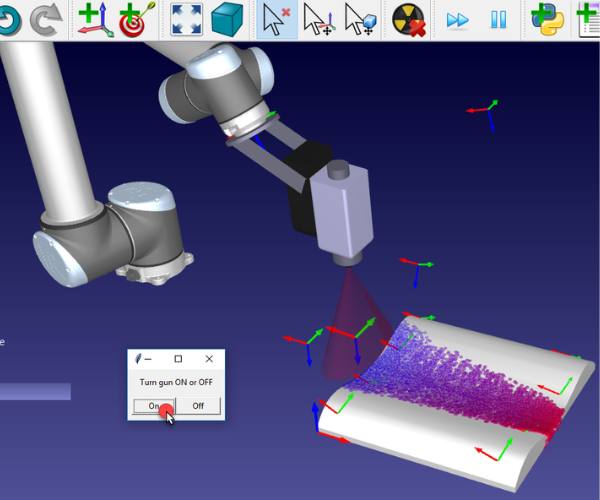

Robot simulation and analysis play a key role in integrating industrial robots. By creating a virtual environment, simulations help test and optimize applications before actual implementation. This process helps identify robot reach limits, space requirements, and fixture clearances. Additionally, it assists in determining equipment placement, robot movement paths, tool types, and transporter needs for robot positioning.

At MadoX, we offer top-tier simulation and offline programming services to boost the performance of robotic process automation services, including:

- 3D Simulation – Visualize robotic operations in a virtual space

- Offline Programming – Develop and test robot programs without disrupting production

- Reachability & Interference Checks – Ensure smooth movement and avoid obstructions

- Cycle Time Optimization – Improve efficiency by reducing operation time

- Work Cell & Workflow Layout Optimization – Enhance workspace design for better productivity

- Variation Simulation Analysis – Predict and address potential variations in processes

We utilize advanced software such as ABB Robot Studio, FANUC Roboguide, KUKA.Sim, Yaskawa MotoSIM EG, Siemens RobCAD/Process Simulate, and RoboDK to deliver precise and efficient solutions.

Robot On-Site Programming

Our experienced team of engineers offers on-site robot programming services to enhance process efficiency. Fine-tuning robot programs on-site is essential for optimizing performance. Our skilled engineers have in-depth application knowledge and hands-on expertise.

We provide programming solutions for robots from leading brands like ABB, Fanuc, KUKA, Yaskawa, Mitsubishi, and more. With international experience working with multiple companies across Europe, we specialize in various robotic applications, including:

- Assembly Automation

- Welding: MIG, TIG, and Spot Welding

- Cutting: Laser & Plasma Cutting

- Material Handling: Pick & Place, Palletizing

- Machine Tending: Press, Injection Molding, Die Casting, CNC Machines

- Vision-Based Applications

- Deburring

- Dispensing

- Inspection

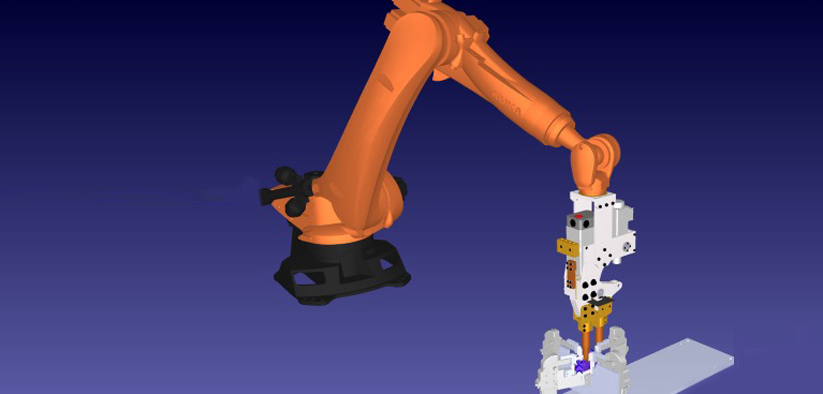

Robot Tool Design & Validation

We create End of Arm Tools (EOAT) tailored to customer needs and site conditions. Our designs incorporate various mechanisms, including vacuum, electromagnetic, servo, mechanical grippers, and weld guns. Additionally, we provide simulation services to test algorithms, configure robots, and conduct regression testing using realistic scenarios. This ensures a strong physics engine, high-quality visuals, and user-friendly programming interfaces.